18507999558

18507999558

Search

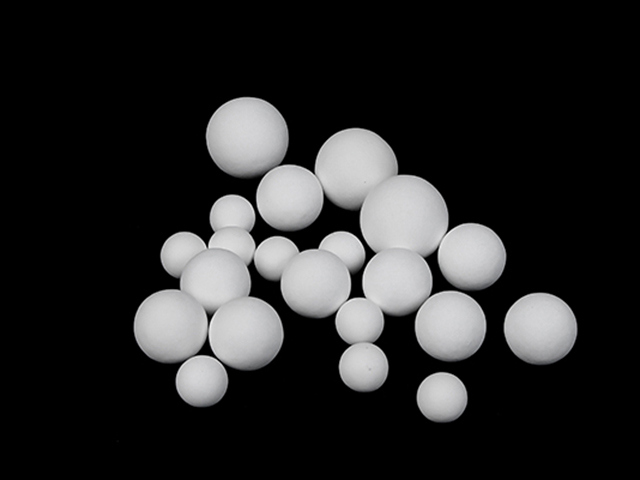

High alumina ceramic balls (catalyst support filler) are made from aluminum oxide powder with very low silicon content. Its high purity and strength make it extremely resistant to high temperature and is used in the reaction tower to avoid the leaching of silica soil covering downstream equipment or forming dirt or toxic catalyst carrier. It is widely used in petroleum, chemical industry, chemical fertilizer, natural gas and environmental protection industries. It is used as covering and supporting material of catalyst in reactor and packing of tower. It has the characteristics of high temperature and high pressure resistance, low water absorption and stable chemical properties. Can withstand the corrosion of acid, alkali and other organic solvents, and can withstand temperature changes during production. Its main role is to increase the gas or liquid distribution point, support and protect the strength of the active catalyst is not high.

● High aluminum grinding ball, with high density, mechanical strength, good wear resistance, is an economical, widely used non-metal grinding medium. The products are widely used in machinery, electronics, aerospace and other fields.

product | Al2O3 % | The mass density g/cm2 | Bibulous rate % | Mohs hardness scale | Wear rate % | color |

High aluminum grinding ball | 92 | 3.65 | 0.01 | 9 | 0.011 | white |

Cosmetic requirements | ||||||

High alumina grinding balls | ||||||

cracking | Don't allow | |||||

impurities | Don't allow | |||||

Bubble hole | 1mm The above is not allowed,0.5mm 3 / ball allowed inside。 | |||||

defects | Max size 0.3mm 3 / ball, | |||||

advantages | A) High aluminum content B) high density C) high hardness D) High wear resistance | |||||

Index of the Item | Value The numerical |

Bibulous rate | <1 |

The mass density | 1.9-2.2 |

True proportion | >3.6 |

Operating temperature | 1650 |

porosity | <1 |

Mohs hardness | >9 |

Acid degree | >99.6 |

Alkali degree | >85 |

size | The compressive strength | |

Kg/star | Thousands of cattle/star | |

3mm | >203 | >2 |

6mm | >459 | >4.6 |

13mm | >877 | >8.7 |

19mm | >1220 | >12 |

25mm | >1630 | >16 |

38mm | >2340 | >23 |

50mm | >3460 | >34 |

Copyright © Jiangxi Aite Mass Transfer Technology Co., Ltd. Gan ICP is prepared 2021000504-1

Company address: the intersection of Jinguang Avenue and Chongqing Middle Road, Anyuan Industrial Park, Pingxiang City, Jiangxi Province