18507999558

18507999558

Search

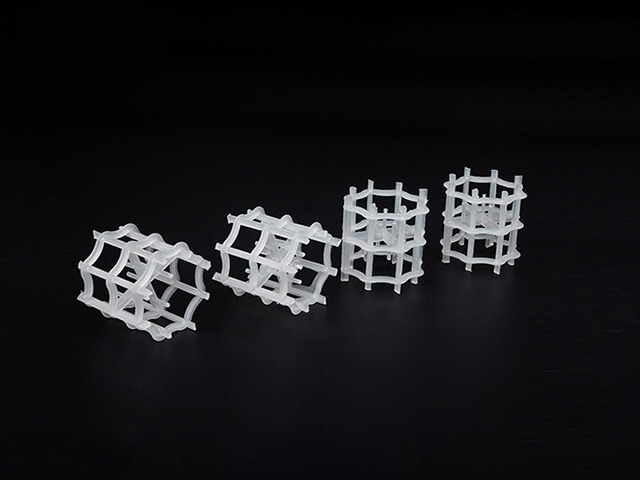

Plastic 84 has the advantages of large internal arc voidage, small pressure drop, low height of mass transfer unit, high flooding point, large gas-liquid contact area, light specific gravity, large mass transfer efficiency and so on. Widely used in petroleum, chemical, chlor-alkali, gas, environmental protection and other industries in the packed tower.

Plastic 84 inner arc ring packing is also known as Mailer ring packing. Plastic B84 inner arc ring packing is characterized by large open area of ring wall, so plastic B84 inner arc ring packing has the characteristics of large flux, small resistance and high mass transfer efficiency.

● The structure makes its large flow, low pressure, good mechanical strength.

● The packing has reasonable geometric symmetry, good uniformity and high voids, eight arcs and four arcs along the axial alternate arrangement, each arc along the radial ring fold into the ring, so that the packing surface is continuous and open, and evenly distributed in space, compared with the Ball ring, flux can be increased by 15-30%, pressure drop 20-30%. It is recognized as an extremely efficient tower packing.

| The product name | Plastic eight-four inner arc ring | |||

| The material | PP,PE,PVC,CPVC,PVDF ,PTFE | |||

| The service life of the | >3 years | |||

| size | Specific surface area m2/m3 | Void fraction | Accumulation number | Packing weight |

| mm | % | per/ m3 | Kg/m3 | |

| 25 | 185 | 93 | 55000 | 60 |

| 38 | 138 | 94 | 16000 | 58 |

| 50 | 121 | 95 | 5500 | 45 |

| 90 | 40 | 97 | 1180 | 30 |

| performance | Large voidage, low pressure, low height of mass transfer unit, high flooding point, sufficient gas-liquid contact, small specific gravity, high mass transfer efficiency | |||

| advantages | 1. Large flow, low pressure and good mechanical strength. | |||

| 2. Strong corrosion resistance, large void, energy saving and environmental protection, low cost, easy to load and unload light weight. | ||||

| Application field | Plastic bulk packing temperature of 280 degrees Celsius, widely used in petroleum, chemical, chlor-alkali, gas, environmental protection and other industries in the packing tower. | |||

| Properties/Materials | PE | PP | RPP | PVC | CPVC | PVDF |

| Density (after injection) | 0.98 | 0.96 | 1.2 | 1.7 | 1.8 | 1.8 |

| Operating temperature | 90 | >100 | >120 | >60 | >90 | >150 |

| Corrosion resistance | GOOD | GOOD | GOOD | GOOD | GOOD | GOOD |

| The compressive strength | >6.0 | >6.0 | >6.0 | >6.0 | >6.0 | >6.0 |

Copyright © Jiangxi Aite Mass Transfer Technology Co., Ltd. Gan ICP is prepared 2021000504-1

Company address: the intersection of Jinguang Avenue and Chongqing Middle Road, Anyuan Industrial Park, Pingxiang City, Jiangxi Province