18507999558

18507999558

Search

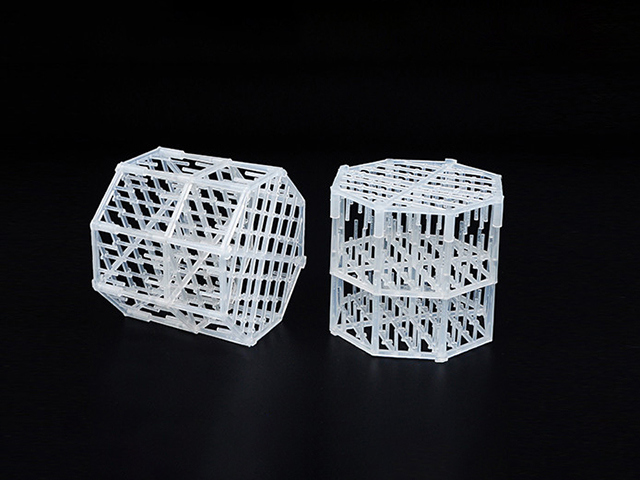

Plastic Q Parker is suitable for many different drinking water treatment processes, such as: biological treatment, physical filtration, pretreatment for seawater desalination, drinking water treatment Q.

Puck has large porosity and surface area and is ideal as a biological treatment medium for drinking water. Biofilm is a good treatment process for raw water containing ammonia, manganese, iron, etc. Q Parker can be used in different ways in the traditional filtering process. The media dual filter Q Parker can be used in combination with sand. Tests have shown that Q Parker operates as well as or better than traditional media in these types of filters. Q Parker can be used not only in traditional drinking water treatment, but also in brine treatment. An important part of a desalination plant is the pretreatment process. Q Parker is an excellent filtration medium for pretreatment filtration of seawater desalination plants.

Plastic bulk tower packing is made of polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polyvinylidene (PVDF), polytetrafluoroethylene (PTFE) tower packing. High voidage, low pressure drop, low mass transfer unit height, high flooding point, full gas-liquid contact, small specific gravity, high heat and mass transfer efficiency. The operating temperature of these plastic bulk fillers can be in 60-280 degrees Celsius.

| The product name | Plastic Q Parker | ||||

| The material | PP,PE,PVC,CPVC,PVDF ,PTFE | ||||

| The service life of the | >3 years | ||||

| size | Drip several | Void fraction % | Accumulation number | Packing weight | Dry packing factor |

| 82.5*95 | 388 | 96.3 | 1165 | 33.7 | 23 |

| performance | Large voidage, low pressure, low height of mass transfer unit, high flooding point, sufficient gas-liquid contact, small specific gravity, high mass transfer efficiency | ||||

| advantages | 1. Large flow, low pressure and good mechanical strength. | ||||

| 2. Strong corrosion resistance, large void, energy saving and environmental protection, low cost, easy to load and unload light weight. | |||||

| Application field | Plastic bulk packing temperature of 150 degrees Celsius, widely used in petroleum, chemical, chlor-alkali, gas, environmental protection and other industries in the packing tower. | ||||

| Properties/Materials | PE | PP | RPP | PVC | CPVC | PVDF |

| Density (after injection) | 0.98 | 0.96 | 1.2 | 1.7 | 1.8 | 1.8 |

| Operating temperature | 90 | >100 | >120 | >60 | >90 | >150 |

| Corrosion resistance | GOOD | GOOD | GOOD | GOOD | GOOD | GOOD |

| The compressive strength | >6.0 | >6.0 | >6.0 | >6.0 | >6.0 | >6.0 |

Copyright © Jiangxi Aite Mass Transfer Technology Co., Ltd. Gan ICP is prepared 2021000504-1

Company address: the intersection of Jinguang Avenue and Chongqing Middle Road, Anyuan Industrial Park, Pingxiang City, Jiangxi Province