18507999558

18507999558

Search

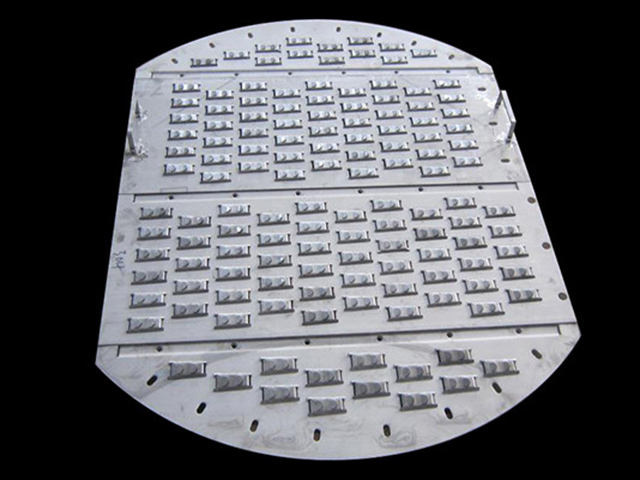

Float valve tray is a commonly used tray, it opens many square or circular holes in the tray, each hole has a valve plate, the gas through the valve hole will valve plate up, horizontal direction injection, through the liquid layer, gas and liquid reinforce each other in the foam state heat transfer, mass transfer process. Because the opening of the valve plate can change with the gas speed, the valve plate can be automatically closed down under the action of gravity at low gas speed, which reduces the leakage. Therefore, it has the advantages of high efficiency and large elasticity. And the structure is simple, the cost is low, the processing ability is high.

● The processing capacity is smaller than the tongue and sieve tray, and the processing capacity is about 20%~40% larger than the bubble cap tray

● The operation elasticity of the valve tray is higher than that of the round bubble cap, tongue shape and sieve plate. The elasticity of the tray is allowed to be in the chamber of the tray fluid mechanics. The valve tray can maintain high efficiency within the wide variation of the air-liquid load chamber

● The pressure drop of the dry plate is larger than that of the tongue and sieve plate, and smaller than that of the bubble cap tray. The gradient of the liquid level on the tray is also smaller

● Foam entrainment quantity is smaller than tongue shape, bubble cap, slightly larger than sieve plate

Copyright © Jiangxi Aite Mass Transfer Technology Co., Ltd. Gan ICP is prepared 2021000504-1

Company address: the intersection of Jinguang Avenue and Chongqing Middle Road, Anyuan Industrial Park, Pingxiang City, Jiangxi Province